As supply chain management becomes increasingly complex and data-driven, innovative technologies such as Ambient IoT are emerging to provide new solutions to longstanding challenges. Ambient IoT refers to the use of energy-harvesting sensors that operate without batteries, drawing power from environmental sources such as light and radio frequencies. These sensors are instrumental in streamlining supply chain operations by providing real-time data on critical parameters like temperature, humidity, and location. Unlike traditional sensors that are often hampered by the lifespan and replacement cost of batteries, Ambient IoT offers a sustainable and cost-effective alternative. The move towards batteryless sensors is a response to the need for enhanced efficiency and reduced costs, positioning Ambient IoT as a transformative force in supply chain logistics. Companies like Energous are at the forefront of this technological wave, contributing to drastic changes in how inventory is tracked and managed across varied industries.

The Role of Batteryless Sensors in Supply Chains

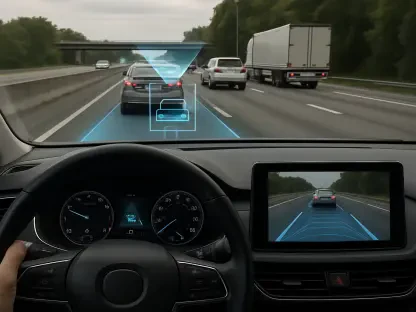

Ambient IoT introduces a paradigm shift from conventional methods of monitoring and controlling supply chain operations. Batteryless sensors, such as those developed by Energous with their e-Sense tag, are ushering in a new era. While this technology is not without its challenges, like slightly higher costs or shorter connectivity ranges compared to some competitors, its impact is noteworthy. These batteryless sensors can transmit data over distances of up to five meters and are integrated efficiently within supply chain operations. This enables real-time monitoring, ensuring conditions such as temperature and humidity are maintained within specified levels. With environmental energy-harvesting capabilities, sensors are becoming indispensable in the modern supply chain landscape, providing companies with a sustainable method to ensure product quality and compliance throughout the logistics process. As industries continue to strive for greater efficiency, the shift to Ambient IoT exemplifies the ongoing evolution toward more versatile and economical solutions.

The use of batteryless sensors also introduces critical cost-saving measures by eliminating the need for frequent battery replacements and maintenance, which not only disrupts operations but also adds to the overall operational costs. These efficiencies result in cumulative cost savings over time, enabling businesses to allocate resources to other strategic areas. Furthermore, Ambient IoT’s seamless integration with cloud-based data systems facilitates the collection and analysis of big data, offering valuable insights that can enhance operational decision-making. The PowerBridge transmitter systems from Energous exemplify this advancement by ensuring sufficient RF power support for transmitting this vital data to the cloud. This capability is quickly becoming a standard expectation as more companies recognize its potential to drive efficiency in increasingly competitive markets. As each sensor networks with others, a cohesive and comprehensive overview of the supply chain’s operational health becomes possible, granting businesses an unprecedented level of control and insight.

Transformative Impact on Industry Efficiency

In line with broader trends toward adopting cleaner and more efficient technologies, the growth of Ambient IoT technology is gaining significant momentum. Market Research Intellect projects an exponential increase in its adoption, particularly across Europe. The anticipated market growth from $1.2 billion in 2024 to $3.5 billion by 2031 highlights the demand trajectory and underscores the role of Ambient IoT in revolutionizing industry standards. Major European countries with robust industrial sectors, such as Germany and France, are leading this transition, leveraging Ambient IoT to bolster their supply chain resilience and adaptability. As other regions observe these successes, it prompts wider adoption, catalyzing a global shift toward similar innovative solutions and setting new benchmarks in supply chain management.

Beyond mere cost and environmental benefits, Ambient IoT technology equips companies with strategic capabilities that are pivotal in addressing one of the most pressing supply chain challenges: unpredictability. The enhanced data accuracy and real-time updating features of these systems allow firms to preemptively address potential disruptions by employing predictive analytics. This advancement not only ensures smooth operations but also prepares companies to react swiftly to any unforeseen changes or demands. Furthermore, this data-driven approach fosters transparency and enhances communication across the various segments of the supply chain, from suppliers to end customers. As firms increasingly rely on such technology, the landscape of supply chain management fundamentally transforms, providing firms with a competitive edge through optimized logistics and responsive operations.

Future Implications and Considerations

As supply chain management becomes more intricate and reliant on data, new technologies like Ambient IoT are surfacing to address long-standing challenges. Ambient IoT involves energy-harvesting sensors that function without batteries, instead drawing energy from environmental sources such as light and radio waves. These sensors are critical in optimizing supply chain operations by offering real-time data on essential factors like temperature, humidity, and location. Traditional sensors often struggle with the limitations of battery life and the cost of replacements, but Ambient IoT provides a sustainable, cost-effective alternative. The shift to batteryless sensors is driven by the demand for increased efficiency and reduced expenses, placing Ambient IoT at the forefront of supply chain logistics innovation. Companies such as Energous spearhead this technological movement, bringing significant transformation in inventory tracking and management across various industries. Ambient IoT promises a revolution in how businesses handle their supply chains, emphasizing sustainability and precision.