Imagine a factory floor where machines communicate with each other, predict their own breakdowns before they happen, and schedule maintenance without human intervention. This isn’t science fiction—it’s the reality being forged by Industry 4.0, the fourth industrial revolution that’s reshaping how industries manage their fixed assets. From manufacturing plants to oil rigs, the tools of this digital era, including artificial intelligence, smart sensors, and virtual replicas, are driving a transformation in the way companies handle machinery, equipment, and infrastructure. Projections show the industrial fixed asset management market soaring from USD 54.83 billion in 2024 to an astonishing USD 289.21 billion by 2033, with an annual growth rate of 20.4%. Such staggering figures highlight the urgency and potential of this shift. As businesses strive to cut costs, reduce downtime, and boost efficiency, the influence of cutting-edge technologies promises to redefine asset management over the next decade. Let’s delve into the key forces driving this change and what they mean for industries by 2033.

Harnessing Digital Tools for Smarter Asset Oversight

At the heart of Industry 4.0 lies a suite of digital innovations that are revolutionizing fixed asset management across diverse sectors. The Internet of Things (IoT) stands out as a cornerstone, embedding sensors into equipment to enable real-time monitoring of performance and condition. This connectivity allows businesses to gather vast amounts of data on everything from temperature fluctuations to wear and tear, creating a detailed picture of asset health. Unlike traditional methods that often rely on scheduled checkups or reactive repairs, IoT empowers a proactive stance. Companies can now detect anomalies early, preventing minor issues from escalating into costly failures. As a result, downtime shrinks, and operational efficiency gets a significant boost. By 2033, this level of connectivity is expected to be ubiquitous, forming the backbone of asset management strategies in industries like energy, utilities, and construction, where every minute of operation counts.

Beyond IoT, the integration of cloud and edge computing adds another layer of sophistication to asset oversight. Cloud platforms provide a centralized hub for storing and analyzing data, making it accessible to teams across global operations. Meanwhile, edge computing tackles the challenge of latency by processing data closer to the source, which is a lifesaver for remote sites like mining operations or offshore rigs with spotty connectivity. This dual approach ensures that insights are delivered swiftly, enabling rapid responses to emerging issues. Picture an oil and gas facility in a far-flung location instantly diagnosing a pump issue without waiting for data to travel halfway across the world. Such capabilities are transforming decision-making, slashing delays, and paving the way for seamless asset management. By 2033, these technologies are set to become even more refined, ensuring industries can maintain peak performance regardless of location or logistical hurdles.

Virtual Models Leading the Charge in Optimization

One of the most intriguing developments under the Industry 4.0 umbrella is the emergence of digital twins—virtual replicas of physical assets that mirror their real-world behavior. These digital counterparts allow companies to simulate countless scenarios, from stress tests to environmental changes, without risking the actual equipment. In sectors like manufacturing and energy, where high-value machinery is critical, this technology offers a way to predict wear, optimize performance, and extend asset lifecycles. By running simulations, businesses can foresee how a turbine might fare under extreme conditions or identify weak points in a production line before they fail. As adoption grows, digital twins are poised to become a standard tool by 2033, offering a crystal ball of sorts for asset managers aiming to stay ahead of potential disruptions while maximizing efficiency.

Further enhancing their appeal, digital twins integrate seamlessly with other Industry 4.0 technologies like IoT and AI, creating a powerful synergy. Data from connected sensors feeds into these virtual models, ensuring they reflect the asset’s current state with pinpoint accuracy. Meanwhile, AI algorithms analyze this data to offer actionable insights, such as when to replace a part or adjust operating parameters. This interconnected approach not only sharpens decision-making but also cuts costs by reducing the need for physical testing or unplanned repairs. Major players in the field are already capitalizing on this—think of platforms that orchestrate real-time monitoring and simulation across sprawling industrial networks. By 2033, the widespread use of such integrated systems will likely redefine best practices in fixed asset management, turning what was once a reactive process into a finely tuned, predictive science.

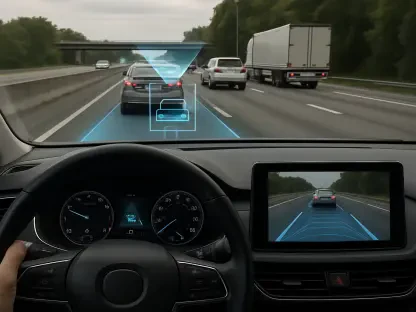

Predictive Maintenance as a Game-Changer for Efficiency

Perhaps nowhere is the impact of Industry 4.0 more evident than in the realm of predictive maintenance, a strategy that uses AI and IoT-driven analytics to foresee equipment failures before they occur. Unlike older methods that rely on fixed schedules or post-breakdown fixes, predictive maintenance leverages real-time data from sensors to monitor asset health continuously. Machine learning algorithms then analyze patterns in this data to flag potential issues, allowing maintenance to be scheduled at the optimal time. This means a factory could avoid a costly shutdown by replacing a worn component just before it fails, saving both time and money. As this approach matures by 2033, it’s expected to become the norm across asset-heavy industries, fundamentally altering how businesses manage the wear and tear of their critical infrastructure.

The ripple effects of predictive maintenance extend far beyond just preventing breakdowns. By minimizing unexpected downtime, companies can streamline production schedules and improve overall reliability, which is crucial in competitive markets like oil and gas or manufacturing. Additionally, this method helps optimize resource allocation—maintenance crews are deployed only when necessary, reducing labor costs and freeing up personnel for other tasks. The financial benefits are clear, with many industries already reporting significant savings as they adopt these tools. Looking ahead to 2033, advancements in AI will likely make these systems even smarter, refining their ability to predict failures with greater precision. This evolution promises to cement predictive maintenance as a linchpin of fixed asset management, ensuring that businesses not only survive but thrive in an era defined by digital transformation and relentless efficiency demands.

Building a Future-Ready Asset Management Ecosystem

Looking back on the trajectory of Industry 4.0, it’s clear that the strides made in fixed asset management reflected a profound shift toward digital integration and foresight. By blending technologies like IoT, digital twins, and predictive analytics, industries tackled challenges that once seemed insurmountable—reducing downtime, extending equipment life, and slashing operational costs. Reflecting on this era, the collaboration between smart systems and human expertise proved to be the key to unlocking unprecedented efficiency across sectors as varied as energy and construction.

Moving forward to 2033 and beyond, the focus should pivot to creating adaptable, scalable ecosystems that can evolve with technological advancements. Industries must prioritize interoperability among tools, ensuring seamless data flow across diverse platforms and asset types. Investing in workforce training will also be critical to bridge the gap between cutting-edge systems and practical application. Ultimately, staying ahead will mean embracing continuous innovation, leveraging insights from today’s successes to build resilient asset management frameworks for tomorrow’s challenges.