In recent years, Industry 4.0 has emerged as a groundbreaking technological revolution, reshaping the manufacturing landscape through the transformative power of Artificial Intelligence (AI) and the Internet of Things (IoT). As businesses strive to maintain competitiveness and efficiency, these advancements offer significant opportunities to enhance operational processes and drive innovation. Patrick Theobald, a leading expert in digital transformation, has provided invaluable insights into the challenges and opportunities presented by this evolving paradigm.

The Entrepreneurial Journey

Patrick Theobald’s entry into the world of entrepreneurship was both unexpected and inspiring. Initially, he had no plans to become a founder, but his deep curiosity about digitalization and its implications led him to establish a thriving company in this innovative space. Driven by a genuine passion for solving industry problems and improving efficiencies, Theobald’s journey underscores the importance of adaptability and vision in achieving success. His commitment to addressing the challenges faced by the manufacturing sector and leveraging digital tools to streamline processes has positioned him as a prominent figure in the field.

Stuttgart: A Hub for Innovation

Stuttgart, as highlighted by Patrick Theobald, serves as a vital center for business, particularly for small and medium-sized enterprises (SMEs). The city is renowned for its mix of hidden champions—companies that play a substantial role in the global economy despite being relatively obscure. These enterprises, often characterized by their specialized expertise and innovative products, contribute significantly to economic growth and technological advancement. Stuttgart’s robust educational institutions also play a crucial role in cultivating the next generation of engineers, fostering a rich environment for innovation and development. This dynamic interplay between industry and academia creates a breeding ground for groundbreaking ideas and solutions.

Potential and Challenges in Digitalization

Patrick Theobald’s fascination with industry digitalization lies in the vast potential for optimization and efficiency that remains largely untapped. In high-wage countries such as Germany, even marginal improvements in efficiency can lead to considerable economic benefits. This potential for enhancement drives Theobald to continuously explore digital transformation projects, taking pleasure in seeing tangible results that contribute to overall productivity and profitability. However, the journey toward digitalization is not without obstacles. SMEs face significant challenges, including a shortage of skilled workers, intense competition from Asian markets, and burdensome bureaucratic processes. Nevertheless, Theobald remains optimistic, advocating for a proactive attitude and less complaining, emphasizing that with the right tools and methodologies, these hurdles can be overcome.

Simplifying Factory Operations with Peakboard

Peakboard, the flagship product developed by Patrick Theobald’s company, aims to simplify factory operations to an intuitive level similar to using an iPhone. One of the primary goals of Peakboard is to address several digitalization issues that factories encounter, such as the elimination of paper-based processes and facilitating seamless access to critical information across multiple data sources. The product’s specialized user interface is tailored to meet the diverse needs of production workers, enhancing overall operational efficiency and productivity. By making complex data readily accessible and easy to interpret, Peakboard empowers workers to make informed decisions and optimize their workflows.

Integrating Advanced Technologies

The technical sophistication of Peakboard is underscored by its ability to connect with various IT and OT systems crucial for digitalization projects. This includes integration with sensors, microcontrollers, Manufacturing Execution Systems (MES), databases, Enterprise Resource Planning (ERP) systems like SAP, and the expansive realm of cloud and AI technologies. The development of such extensive integration capabilities necessitates substantial investment in both technology and expertise. These connections enable Peakboard to provide a comprehensive digital solution that meticulously addresses the nuances of modern manufacturing processes, positioning it as an indispensable tool for achieving digital transformation.

Embracing Emerging Trends and Practical Advice for SMEs

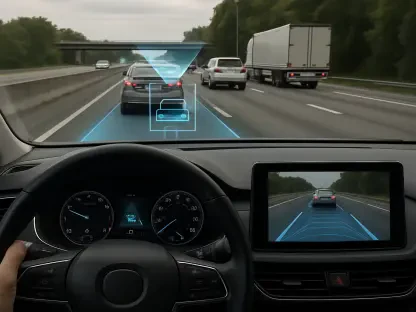

In recent years, Industry 4.0 has emerged as a revolutionary force within the manufacturing sector, fundamentally changing how we approach production and operational efficiency. Leveraging the capabilities of Artificial Intelligence (AI) and the Internet of Things (IoT), this technological advancement has introduced a new era where machines and systems can communicate and optimize workflows autonomously. As businesses strive to stay competitive and boost efficiency, these innovations offer substantial opportunities to refine operational procedures and foster groundbreaking innovation. Patrick Theobald, an esteemed authority on digital transformation, has shed light on the complexities and prospects ushered in by this dynamic shift. His expertise highlights how companies can navigate the challenges and harness the potential of Industry 4.0, ensuring they remain at the forefront of technological progress. Adapting to these changes is crucial for companies looking to not only survive but thrive in an increasingly digital and interconnected world.