With us today is Matilda Bailey, a networking specialist whose work is at the forefront of cellular, wireless, and next-generation connectivity solutions. We’re delving into Germany’s ambitious new initiative, a €1 billion AI center in Munich, to understand its strategic importance for European industry and its place in the global technology race.

Finance Minister Klingbeil highlighted “digital sovereignty” as a key goal for the new €1 billion AI center. Beyond just hosting data in Europe, what specific capabilities does this facility provide to reduce reliance on foreign tech, and what are the first practical steps for German companies to leverage it?

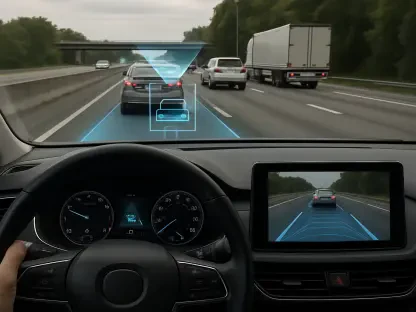

This initiative is about much more than just data storage; it’s about creating a complete, self-sufficient ecosystem for industrial innovation. The center, powered by a collaboration between Deutsche Telekom and Nvidia, provides the immense computing power needed to develop and train complex AI systems right here in Germany. This is a critical step in building what the Finance Minister calls “technological leadership.” For German companies, the first practical step is to view this facility as an R&D powerhouse. They can now access world-class infrastructure to connect their industrial data sources with sophisticated AI models, all without relying on infrastructure outside of Europe. This move directly strengthens their ability to innovate securely and independently.

The initiative focuses on an “industrial AI cloud” rather than competing directly with the US on consumer-facing AI. Could you elaborate on this strategy? What specific manufacturing challenges will this approach solve, and how does it uniquely leverage Europe’s existing industrial strengths?

This is an incredibly shrewd strategic decision. Instead of trying to beat US tech giants at their own game of building massive large language models for consumers, this initiative plays to Europe’s core strengths. We have a world-renowned manufacturing and industrial base, and this “industrial AI cloud” is designed specifically to serve that sector. Think about challenges like predictive maintenance for factory machinery, optimizing complex supply chains in real-time, or developing new materials through simulation. This center provides the specialized environment to solve those problems by linking AI directly to industrial data. It’s about making our existing industrial power smarter and more efficient, creating a distinct competitive advantage where we are already strong.

With major corporations like Deutsche Telekom, Nvidia, and SAP involved, this is a significant public-private push. Can you detail the distinct role each partner plays in this ecosystem and provide an example of how their collaboration will directly speed up AI adoption in Germany’s industrial sector?

Each partner brings a crucial piece of the puzzle, creating a powerful synergy. Deutsche Telekom provides the foundational infrastructure and robust connectivity, essentially building the physical “factory” and ensuring data flows securely. Nvidia contributes its world-leading hardware and expertise in AI computing, which is the high-performance engine that runs the complex models. Then you have SAP, a giant in enterprise software, supplying the platforms and applications that allow businesses to actually use the AI with their existing operational data. A clear example of this collaboration in action would be a car manufacturer using SAP’s platform, running on Deutsche Telekom’s infrastructure and powered by Nvidia’s chips, to analyze production line data and predict equipment failures before they happen, saving millions in downtime.

The center is expected to boost Germany’s AI computing power by roughly 50%. Can you translate this metric into tangible outcomes? What kinds of complex industrial simulations or AI models can now be developed locally that were previously out of reach for German businesses?

A 50% increase is a massive leap in capability. In tangible terms, it means German businesses can now tackle problems that were simply too computationally expensive before. We’re talking about creating a complete “digital twin” of an entire factory to simulate and optimize every single process, or running sophisticated AI models to design next-generation materials with specific properties for aerospace or automotive industries. Previously, a mid-sized engineering firm might have had to rely on foreign cloud providers for such tasks, facing high costs and data sovereignty concerns. Now, they can develop these cutting-edge solutions locally, accelerating innovation and keeping their intellectual property secure within Europe.

While one billion euros is a major investment, US tech giants are spending hundreds of billions on AI capacity. How can this German “AI factory” realistically compete and create a distinct advantage? Please outline the long-term strategy to scale this initiative and maintain its relevance.

You’re right, we can’t compete on sheer capital alone. The strategy here isn’t to outspend, but to outsmart by focusing on a specialized niche. The advantage of this “AI factory” is its deep integration with the industrial sector, creating a tailored ecosystem that a general-purpose cloud provider in the US can’t easily replicate. The long-term strategy is to build a flywheel effect: as more industrial companies use the center, they generate more specialized data and develop unique AI applications, which in turn attracts more companies. The key to maintaining relevance is to become the undeniable center of gravity for industrial AI in Europe, fostering a unique ecosystem of expertise, specialized models, and secure data that becomes indispensable for the continent’s manufacturing core.

What is your forecast for Europe’s industrial AI ecosystem over the next five years?

My forecast is one of focused, accelerated growth. Over the next five years, I expect we’ll see this industrial AI ecosystem become a significant differentiator for European manufacturing. We won’t be leading in consumer AI chatbots, but we will see German and European companies setting the global standard for AI-driven production, smart logistics, and sustainable manufacturing. This initiative in Munich is a foundational pillar. It will inspire similar specialized hubs across the continent, creating a network that solidifies Europe’s position not just as a user of AI, but as a creator of high-value, industrial artificial intelligence solutions that will define the next generation of industry.