The next frontier of artificial intelligence is not about processing more data but about fundamentally understanding the physical laws that govern our world, a challenge that has brought two technology giants together in a landmark partnership. In a move poised to reshape heavy industry, Nvidia and French software leader Dassault Systèmes have joined forces to create a new class of digital twin platforms. This collaboration aims to merge Dassault’s sophisticated virtual twin technology with Nvidia’s end-to-end AI ecosystem to deliver industrial solutions that are not just intelligent but are also grounded in the immutable principles of science. The initiative represents a pivotal shift from abstract AI concepts toward a tangible engineering discipline designed for the most demanding real-world applications.

When an AI Needs to Understand Gravity

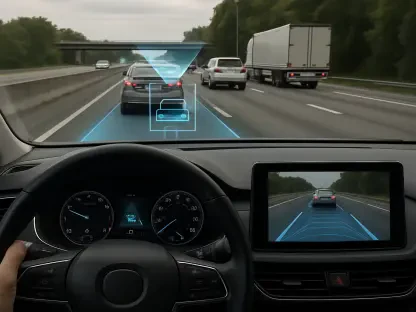

For years, artificial intelligence has excelled at identifying patterns within vast datasets, enabling predictive capabilities across numerous fields. However, a critical gap has persisted: the disconnect between predictive AI and an AI that can truly comprehend and operate within the laws of physics. A standard AI model can forecast a component’s failure based on historical data, but it lacks an intrinsic understanding of the material stress, thermal dynamics, or gravitational forces that cause the breakdown. This limitation prevents AI from being fully trusted in environments where physical accuracy is paramount.

This challenge is magnified when designing hyper-complex systems, such as the next generation of liquid-cooled data centers. The intricate interplay of fluid dynamics, power distribution, and thermal management makes traditional design and testing methods prohibitively expensive and slow. In this context, virtual simulation evolves from a helpful tool into an indispensable necessity. Creating a digital replica that behaves exactly like its real-world counterpart allows engineers to test, iterate, and optimize in a virtual space before a single physical component is manufactured, de-risking massive investments and accelerating innovation.

The High Stakes Demand for a Digital Reality Check

The inherent risks of deploying purely data-driven AI models in mission-critical sectors like energy and aerospace are substantial. An algorithm trained only on past data may fail to account for novel scenarios or subtle physical variables, leading to potentially catastrophic outcomes. This reality has fueled the explosive growth of the digital twin market, which is projected to expand significantly by 2033 as industries seek to validate and de-risk their operations through high-fidelity simulations. The demand is no longer just for intelligence but for certifiable reliability.

This market-wide shift underscores the industrial imperative for “trustworthy AI.” For an AI system to be adopted in a power plant or an automotive assembly line, its recommendations must be verifiable and scientifically sound. The partnership between Nvidia and Dassault directly addresses this need by creating a platform where AI-driven insights are continuously checked against a physics-based virtual twin. This ensures that the AI’s decisions are not just statistically probable but are also physically plausible and safe for real-world implementation.

Deconstructing the Alliance

At the heart of this alliance is a powerful synergy between two distinct but complementary technology stacks. Dassault Systèmes contributes its world-leading virtual twin platform, 3DEXPERIENCE, which provides the framework for creating scientifically accurate digital replicas of complex industrial systems. Nvidia complements this with its comprehensive AI ecosystem, including its hardware, open models, and software libraries, which serve as the “brain” to analyze, optimize, and interact with these virtual worlds. Together, they form a closed loop where simulation informs AI, and AI enhances the simulation.

This integration gives rise to the “Physical AI” paradigm, a concept championed by Nvidia CEO Jensen Huang. It describes an artificial intelligence grounded in the physical sciences, capable of moving from simple prediction to genuine understanding. By learning within a simulated environment that obeys the laws of physics, the AI develops an intuition for how real-world systems operate. This evolution marks the maturation of the “AI factory” from a marketing buzzword into a tangible engineering discipline, where simulation and model-based design are the core pillars for building reliable industrial intelligence.

Expert Perspectives on a Turning Point

The strategic importance of this collaboration is echoed by leaders and analysts across the industry. Dassault Systèmes CEO Pascal Daloz emphasized that the primary goal is to create a platform for “trustworthy” and scalable “industrial AI.” He highlighted that by grounding AI in scientific first principles, enterprises can move beyond experimentation and confidently deploy intelligent systems to solve their most complex engineering and operational challenges. The focus is on building a foundation of trust that will accelerate AI adoption in risk-averse sectors.

Further validation comes from observing Nvidia’s own practices. Industry analyst Stephen Sopko pointed out the significance of Nvidia using Dassault’s model-based systems engineering (MBSE) to design its own next-generation Rubin platform AI data centers. This self-endorsement is a powerful testament to the technology’s value, demonstrating that even a leader in AI infrastructure recognizes that the complexity of modern systems requires the sophisticated planning and simulation capabilities offered by digital twins. It signals that designing the factories of the future requires the very tools this partnership aims to provide to the broader market.

A Blueprint for Industrial Application

The practical applications of this physical AI platform are poised to transform core industrial operations. In manufacturing, these advanced digital twins will enable companies to simulate entire production lines, optimizing robotic workflows, predicting maintenance needs with pinpoint accuracy, and testing new configurations without disrupting ongoing operations. This leads to enhanced efficiency, reduced downtime, and more resilient supply chains capable of adapting to changing market demands.

Beyond the factory floor, the energy sector stands to gain immense benefits. By creating a physics-informed digital twin of a power grid, operators can simulate various demand scenarios, integrate renewable energy sources more effectively, and predict potential points of failure before they occur. This capability is crucial for enhancing grid stability and reliability. Similarly, data center management can be revolutionized. An AI-powered twin can plan for capacity expansion, optimize power and cooling consumption in real time, and preemptively identify equipment failures, ensuring maximum uptime and operational efficiency for the backbone of the digital economy.

The collaboration between Nvidia and Dassault Systèmes ultimately established more than just a new product; it laid down a new paradigm for how industries will harness artificial intelligence. By insisting that AI learn and operate within the constraints of physical law, the partnership addressed the critical barrier of trust that had long hindered its adoption in high-stakes environments. The initiative signaled a definitive move toward an era of validated, reliable, and scientifically grounded AI, ensuring that the next wave of industrial innovation was built on a foundation of reality.