The proliferation of artificial intelligence into critical sectors such as smart city management and industrial automation has created an urgent demand for computing platforms that can operate far from the pristine conditions of a laboratory. While developer kits based on powerful platforms like the NVIDIA Jetson Orin series have accelerated AI prototyping, they represent a mere starting point, not the final destination for real-world deployment. The journey from a promising proof-of-concept to a reliable, operational system is fraught with environmental challenges—extreme temperatures, moisture, dust, and inconsistent power—that standard hardware is simply not designed to withstand. This critical gap between development and deployment highlights a fundamental truth: the success of any field-based AI initiative hinges less on the sophistication of the algorithm and more on the resilience of the hardware it runs on. For AI to deliver on its promise in these demanding “Pan-Security” domains, it requires a new class of industrial-grade edge devices engineered for unwavering performance and long-term reliability in the field.

The Chasm Between Development and Deployment

Developer kits are invaluable tools for innovation, allowing engineers and data scientists to experiment with AI models for applications like object detection and facial recognition in a controlled setting. However, their design prioritizes accessibility and low cost over durability, making them fundamentally unsuited for mission-critical, continuous operation. These platforms often lack robust thermal management, leaving them vulnerable to performance throttling or outright failure in environments with fluctuating temperatures. Furthermore, their exposed circuit boards and consumer-grade components are susceptible to damage from dust, humidity, and physical shock. Attempting to deploy such a kit in an industrial facility or a roadside enclosure invites frequent “field failures,” leading to operational downtime, costly maintenance, and a loss of confidence in the AI system’s capabilities. The reality is that a lab-grade prototype cannot be expected to deliver the consistent, 24/7 performance required for security monitoring or manufacturing process control without significant and costly modifications that negate its initial benefits.

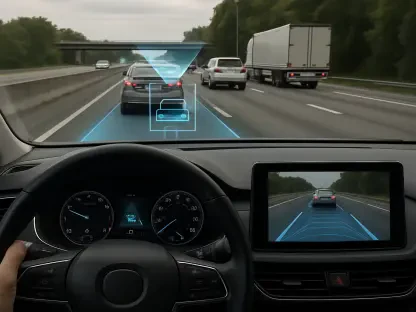

The strategic decision to process data locally at the edge, rather than sending it to a central cloud server, is a cornerstone of modern AI implementation, and it demands specialized hardware to be effective. Performing analytics for tasks like anomaly identification directly on-site provides immense advantages, including near-instantaneous response times, which are critical for safety and security applications. This approach also significantly enhances data privacy by keeping sensitive information, such as video feeds, within a secure local network. Moreover, it drastically reduces the strain on network bandwidth and the associated costs of transmitting vast amounts of raw data. To realize these benefits reliably, the edge computing device must be more than just a processor; it must be a self-sufficient, hardened system capable of operating independently and flawlessly in its designated environment. This necessity drives the demand for industrial-grade AI boxes that are purpose-built to deliver low-latency insights without compromise, bridging the gap between an AI model’s potential and its practical, real-world value.

Engineering for the Unforgiving Real World

True field-readiness is defined by a set of deliberate engineering choices that prepare hardware for the most demanding conditions imaginable. A critical benchmark is the ability to operate reliably across an extreme temperature range, often from -40°C to 70°C, ensuring consistent performance in both freezing winters and scorching summers. This resilience is typically achieved through a combination of a ruggedized, industrial-grade aluminum chassis that aids in passive heat dissipation and an active fan cooling system. Equally important is protection against environmental ingress; a device with an IP65 rating is fully sealed against dust and resistant to low-pressure water jets, making it suitable for outdoor and factory floor deployments. Power stability is another key consideration, with support for a wide 9V–36V DC input to accommodate the variable power sources found in industrial and vehicular settings. These features culminate in an exceptionally high Mean Time Between Failures (MTBF), often exceeding 100,000 hours, which translates to over a decade of expected operational life and a minimal total cost of ownership.

Beyond sheer durability, a field-ready AI system must offer comprehensive connectivity to seamlessly integrate into existing industrial infrastructure. A rich set of built-in interfaces is non-negotiable, as it eliminates the reliance on fragile external hubs and adapters, which are common points of failure. The inclusion of multiple Gigabit Ethernet ports, for instance, allows the device to connect to several IP cameras or network sensors simultaneously. Dual M.2 slots provide flexible expansion options for high-speed NVMe storage and wireless communication modules like 4G/5G or Wi-Fi. Legacy and industrial protocols are also essential, with ports such as USB 3.0 and RS-485 enabling communication with a wide array of sensors, programmable logic controllers (PLCs), and other machinery. This integrated approach not only creates a more robust and streamlined physical installation but also simplifies system architecture, making it easier to deploy, scale, and maintain sophisticated, multi-sensor AI ecosystems without creating a web of failure-prone peripheral devices.

A New Paradigm for Intelligent Infrastructure

The advent of hardware engineered specifically for challenging operational conditions fundamentally altered the trajectory of applied AI. By solving the critical last-mile problem of deployment, these industrial-grade computing boxes removed the primary bottleneck that had long confined powerful AI models to the lab. This shift enabled organizations to confidently transform their passive monitoring systems into proactive, intelligent security and automation ecosystems. The assurance of reliability, backed by extensive environmental testing and long-term warranties, allowed system integrators and end-users to focus their resources on refining AI software and generating actionable insights rather than troubleshooting hardware failures. The result was a dramatic acceleration in the adoption of edge AI for smart cities, critical infrastructure protection, and industrial safety, where uptime and performance are not just desirable but essential. This hardware maturation marked a pivotal moment, proving that the full potential of artificial intelligence could finally be realized at scale in the real world.